Higher inflation and interest rates, low labor availability, supply chain delays, and other factors are creating a perfect tsunami of higher costs required to build, furnish, and decorate a home or commercial building.

Material and commodity costs have risen significantly for home and commercial construction. In June 2022, the Engineering News-Record ENR (Building) Cost Index is 58% higher than in August 2020. As a result, buyers, architects and designers are more often making purchasing decisions based on cost — and sometimes just on product availability.

Door and window manufacturers are among those most affected by material and component costs, shortages and delays. Lumber prices in June 2022 have finally come down 65% from their 2021 highs (which should ease some of the inflationary pressure in the housing market), but price is still relatively high historically. The cost of chlorine, a key input for manufacturing vinyl windows, has increased so much that vinyl windows can now be a more expensive option than fiberglass windows. Stainless steel prices are also higher, impacting cost and availability for hardware including rollers and other bearing assemblies.

OEMs must meet functional buyer expectations for doors and windows, regardless of supply chain difficulties. Things like ease-of-use, design and aesthetics. And understanding of code requirements. Roller assemblies and bearings must be durable, with smooth and quiet operation, and high weight capacity. Whether the motion elements in these applications are internal and unseen, or visible, they must complement the design language of articles they mobilize.

Furthermore, sustainable sourcing goals can also be difficult to manage while there are fewer options available for suppliers and materials. All larger fenestration OEMs are aware of the importance of ESG to their customers, as well as shareholders and employees. For example, vinyl window manufacturers almost always include information about vinyl recycling and recycled content in product marketing. Andersen Windows’ sustainability commitment includes “a lifecycle approach to sustainable product development…from raw materials extraction to end-of-life.” Pella windows’ sustainability page says it is about “providing communities with good jobs, workers with good pay and career opportunities.”

However, when the global supply chain is challenging like it is today, procurement at even the largest companies may consider risking long term reputation for short term cost savings. But even cost-conscious buyers still prefer products made from eco-friendly materials and low-impact manufacturing methods. Especially products designed to reduce household energy consumption. Environment, Social, and Governance (ESG) is becoming more and more important for both residential and commercial buyers. And doors and windows are top of mind for home buyers. In the March 2022 National Association of Realtors (NAR) survey of industry sustainability issues, 51% of respondents found clients were at least somewhat interested in sustainability, and half had been directly involved in the past year with a property that had green features, either on the buyer or seller side. The home features that respondents believed were most important to clients included windows, doors, and siding (36%), proximity to frequently visited places (38%), a comfortable living space (35%), and a home’s utility bills and operating costs (20%).

So how can fenestration industry procurement and engineering organizations balance the need for cost competitiveness with functionality, reliability, and sustainability? Supplier visibility and transparency is key. Partner with suppliers like OMCO SUMO who have decades of design experience, and on the ground operations and relationships in Asia. And keep an open mind to new cost saving designs or assemblies, rather than just looking to source the same thing at a lower price. OMCO SUMO helps fenestration OEMs build strong and sustainable supply chains for standard components, and helps drive material and process cost savings through redesign of more complex assemblies such as rollers or trucks.

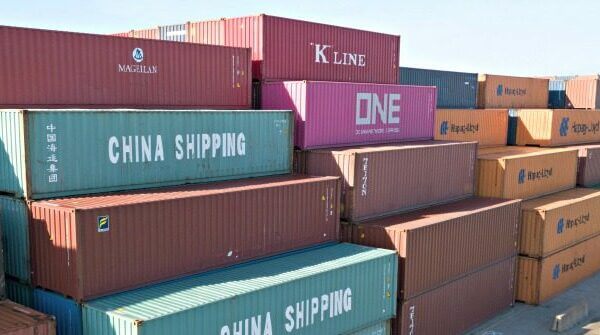

OMCO SUMO engineers and manufacturers many of the products we provide, with facilities and staff in Zhejiang, China for two decades, and long-term partnerships throughout China, Taiwan and India. We maintain precision-machining capabilities at our facility in Wisconsin, as well as a comprehensive Q&A laboratory including state-of-the-art vision inspection and an experienced production staff. For bearing components and assemblies OMCO SUMO provides transparency and assurance of sustainability through our proprietary OMCO Sumo ESG Ratings Report for Ball Bearings. This report is updated quarterly based on OMCO SUMO’s decades of close partnerships and sustainable sourcing throughout Asia. It includes detailed information about the ESG footprint and activity at hundreds of bearing and subcontracted component factories, notable brands they supply, as well as listing all local certifications.

Door and window buyers may be more cost conscious right now, but demand for design, and sustainable production and operation will continue to grow. To meet demand fenestration OEMs need to develop a truly global, sustainable, resilient and redundant supply chain, including hardware components and assemblies (like rollers, trucks, and bearings). Options may include manufacturing in Asia with US assembly. And there are opportunities to consolidate suppliers, and reduce costs and process steps by incorporating bearings and other components into extrusions, castings, mounts, or engineered assemblies. We’d love to hear from you about ways OMCO SUMO can support your product and procurement strategy with manufacturing and sourcing of bearings, value-added engineered assemblies, and other motion-related solutions.

Curious to learn more? Click here to subscribe to the OMCO SUMO Insights newsletter for insights and best practices for sustainable sourcing of bearings, conveyors, and other motion-related products, or contact us directly at info@omcosumo.com. You can also follow us on LinkedIn

OMCO SUMO is a manufacturer and global OEM supplier focused on ESG and sustainable sourcing for bearings, engineered assemblies, and motion-related components across all industries requiring mechanical power transmission. Established in 1964, with our extensive experience and global supplier networks from over 50 years in business, we are deeply knowledgeable and passionate about helping customers achieve sustainable sourcing and ESG goals, focusing on both the integrity of product performance and the corresponding influence on human rights, the environment, and fair business practices. OMCO is the first and only provider of proprietary ESG ratings within the power transmission industry covering an extensive and expanding network of manufacturers throughout Asia that provide high-quality lower-cost products, and often sharing the same supply chain with well-known premium brands without the accompanying overhead. Our goal is to support our customers with transparent values-driven business practices that help achieve sustainability of the triple bottom line: people, profit, and planet.